AAWOOD

Giới thiệu

AAWOOD

Chào mừng Quý Khách ghé thăm trang Web của Công ty TNHH AAWOOD

Chúng tôi xin chân thành gửi lời chúc sức khỏe và tri ân đến Quý Khách hàng

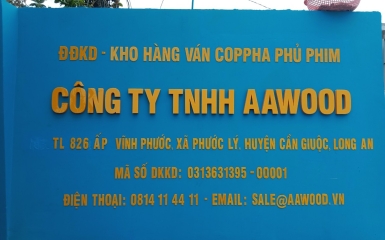

Được thành lập từ đầu năm 2016, AAWOOD hướng đến mục tiêu là nhà cung cấp ván coppha phủ phim hàng đầu trong phân khúc nội địa, chúng tôi luôn không ngừng hoàn thiện hướng đến sự an tâm, tin tưởng và hài lòng của Quý khách hàng.

Bằng tất cả tâm huyết và nổ lực của mình, AAWOOD mong muốn trở thành đơn vị hợp tác đắc lực, tin cậy, phục vụ cho sự phát triển và tạo nên giá trị của Quý khách hàng, Sự lựa chọn của bạn là ưu tiên hàng đầu và quan trọng nhất đối với chúng tôi.

Chúng tôi không chỉ đem đến cho bạn sản phẩm chất lượng mà còn đem đến sự tín nhiệm và mối quan hệ bền vững.

+6500

Năng lực SX (m3/th)

+544

Đơn hàng thực hiện

+90

Dự án đã cung cấp

+44

Khách hàng tin tưởng

" SỰ LỰA CHỌN CỦA BẠN LÀ ƯU TIÊN HÀNG ĐẦU VÀ QUAN TRỌNG NHẤT ĐỐI VỚI CHÚNG TÔI "

tin tức mới

24Tháng 04

CÁCH PHÂN LOẠI VÁN LẠNG VÁN ĐỘN

Thực ra với mỗi khách hàng, mỗi người lại có quan điểm khác nhau về ván lạng, ván độn....

Ván lạng được lạng chủ yếu từ các loại gỗ rừng, gỗ trồng. Nhưng phổ biến nhất là loại ván lạng cao su, ván lạng bạch đàn, ván lạng tràm và ván lạng gỗ thông. Bởi đây là những loại cây dễ trồng, có sức sinh trưởng mạnh mẽ, cây cho thu hoạch nhanh và khả năng tái sinh tốt.

09Tháng 03

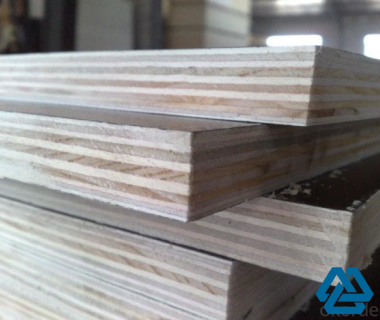

QUY TRÌNH SẢN XUẤT VÁN ÉP PHỦ PHIM AAWOOD

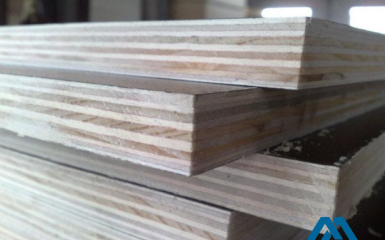

Ván ép coppha phủ phim được tạo nên từ các lớp gỗ lạng mỏng liên kết với nhau bằng keo chuyên dụng chịu nước 100% WBP Phenolic theo phương pháp ép nóng ở nhiệt độ 125oC 140oC. Bề mặt ván được phủ lớp phim Dynea 1 mặt hoặc 2 mặt.

24Tháng 04

CÁCH PHÂN LOẠI VÁN LẠNG VÁN ĐỘN

Thực ra với mỗi khách hàng, mỗi người lại có quan điểm khác nhau về ván lạng, ván độn....

Ván lạng được lạng chủ yếu từ các loại gỗ rừng, gỗ trồng. Nhưng phổ biến nhất là loại ván lạng cao su, ván lạng bạch đàn, ván lạng tràm và ván lạng gỗ thông. Bởi đây là những loại cây dễ trồng, có sức sinh trưởng mạnh mẽ, cây cho thu hoạch nhanh và khả năng tái sinh tốt.

09Tháng 03

QUY TRÌNH SẢN XUẤT VÁN ÉP PHỦ PHIM AAWOOD

Ván ép coppha phủ phim được tạo nên từ các lớp gỗ lạng mỏng liên kết với nhau bằng keo chuyên dụng chịu nước 100% WBP Phenolic theo phương pháp ép nóng ở nhiệt độ 125oC 140oC. Bề mặt ván được phủ lớp phim Dynea 1 mặt hoặc 2 mặt.

24Tháng 04

CÁCH PHÂN LOẠI VÁN LẠNG VÁN ĐỘN

Thực ra với mỗi khách hàng, mỗi người lại có quan điểm khác nhau về ván lạng, ván độn....

Ván lạng được lạng chủ yếu từ các loại gỗ rừng, gỗ trồng. Nhưng phổ biến nhất là loại ván lạng cao su, ván lạng bạch đàn, ván lạng tràm và ván lạng gỗ thông. Bởi đây là những loại cây dễ trồng, có sức sinh trưởng mạnh mẽ, cây cho thu hoạch nhanh và khả năng tái sinh tốt.

09Tháng 03

QUY TRÌNH SẢN XUẤT VÁN ÉP PHỦ PHIM AAWOOD

Ván ép coppha phủ phim được tạo nên từ các lớp gỗ lạng mỏng liên kết với nhau bằng keo chuyên dụng chịu nước 100% WBP Phenolic theo phương pháp ép nóng ở nhiệt độ 125oC 140oC. Bề mặt ván được phủ lớp phim Dynea 1 mặt hoặc 2 mặt.

24Tháng 04

CÁCH PHÂN LOẠI VÁN LẠNG VÁN ĐỘN

Thực ra với mỗi khách hàng, mỗi người lại có quan điểm khác nhau về ván lạng, ván độn....

Ván lạng được lạng chủ yếu từ các loại gỗ rừng, gỗ trồng. Nhưng phổ biến nhất là loại ván lạng cao su, ván lạng bạch đàn, ván lạng tràm và ván lạng gỗ thông. Bởi đây là những loại cây dễ trồng, có sức sinh trưởng mạnh mẽ, cây cho thu hoạch nhanh và khả năng tái sinh tốt.

09Tháng 03

QUY TRÌNH SẢN XUẤT VÁN ÉP PHỦ PHIM AAWOOD

Ván ép coppha phủ phim được tạo nên từ các lớp gỗ lạng mỏng liên kết với nhau bằng keo chuyên dụng chịu nước 100% WBP Phenolic theo phương pháp ép nóng ở nhiệt độ 125oC 140oC. Bề mặt ván được phủ lớp phim Dynea 1 mặt hoặc 2 mặt.

24Tháng 04

CÁCH PHÂN LOẠI VÁN LẠNG VÁN ĐỘN

Thực ra với mỗi khách hàng, mỗi người lại có quan điểm khác nhau về ván lạng, ván độn....

Ván lạng được lạng chủ yếu từ các loại gỗ rừng, gỗ trồng. Nhưng phổ biến nhất là loại ván lạng cao su, ván lạng bạch đàn, ván lạng tràm và ván lạng gỗ thông. Bởi đây là những loại cây dễ trồng, có sức sinh trưởng mạnh mẽ, cây cho thu hoạch nhanh và khả năng tái sinh tốt.

09Tháng 03

QUY TRÌNH SẢN XUẤT VÁN ÉP PHỦ PHIM AAWOOD

Ván ép coppha phủ phim được tạo nên từ các lớp gỗ lạng mỏng liên kết với nhau bằng keo chuyên dụng chịu nước 100% WBP Phenolic theo phương pháp ép nóng ở nhiệt độ 125oC 140oC. Bề mặt ván được phủ lớp phim Dynea 1 mặt hoặc 2 mặt.

video clip