20Tháng 06

THỊ TRƯỜNG VÁN COPPHA THỜI COVID

Trong những năm gần đây, ngành gỗ nói chung và Ván coppha phủ phim nói riêng là điểm sáng với những hoạt động sản xuất, xuất khẩu gỗ và những sản phẩm gỗ sang các thị trường Mailaisia, Thái Lan, Nhật Bản hay Hàn Quốc…với tốc độ tăng trưởng cao và ổn định

20Tháng 06

CHẤT LƯỢNG KEO TRONG SẢN XUẤT VÁN PHỦ PHIM

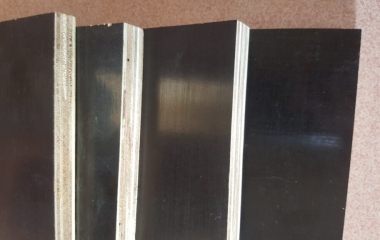

Ván ép phủ keo WBP (loại keo melamine thường) có thể nấu trong nước sôi từ 4-8 tiếng mà không bị tách lớp, trong khi ván ép phủ keo WBP (loại keo melamine tốt hơn) có thể ở trong tình trạng như trên từ 10 đến 20 Tiếng

20Tháng 06

ĐẶC TÍNH CỦA VÁN ÉP COPPHA PHỦ PHIM

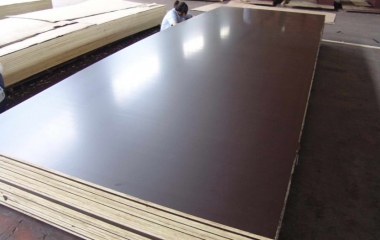

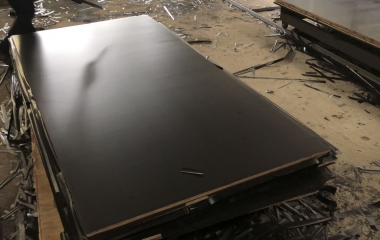

Ván phủ phim (Film Faced Plywood) hay ván khuôn được sử dụng làm ván mặt cốp pha trong các công trình xây dựng cao cấp như khách sạn, chung cư cao tầng, biệt thự, công trình dân dụng và công nghiệp, đường hầm giao thông, lót sàn container, lót sàn tàu biển v.v.v

20Tháng 06

CHỌN LỌC NGUYÊN LIỆU CHO VÁN ÉP PHỦ PHIM

Để có sản phẩm vừa đẹp, vừa chắc chắn và bền bỉ thì nguyên liệu luôn phải được lựa kĩ lưỡng. Ván coppha phim cũng vậy. Nó có rất nhiều loại và được dân trong nghề gọi là độn. Độn cũng có nhiều loại độn như loại A, loại B và loại C. Gỗ làm độn cũng ảnh hưởng đến kỹ thuật và chất lượng của thành phẩm vì thế ở AAWOOD chúng tôi khâu lựa chọn nguyên liệu cũng luôn được quân tâm kỹ lưỡng.

20Tháng 06

NHỮNG LOẠI VÁN ÉP COPPHA TRONG XÂY DỰNG

Với sự ứng dụng đa dạng từ ván coppha thì trên thị trường ngay nay xuất hiện rất nhiều loại ván ép coppha chất lượng. Vậy những loại ván ép coppha đó là những loại nào hãy cùng AAWOOD tìm hiểu ngay nhé.

24Tháng 04

CÁCH PHÂN LOẠI VÁN LẠNG VÁN ĐỘN

Thực ra với mỗi khách hàng, mỗi người lại có quan điểm khác nhau về ván lạng, ván độn....

21Tháng 04

TIÊU CHÍ LỰA CHỌN VÁN ÉP PHỦ PHIM

Với kinh nghiệm lâu năm sản xuất, xuất khẩu sản phẩm gỗ ván ép phủ phim và cung cấp vật tư cho các nhà thầu lớn, nhỏ AAWOOD đã đúc kết ra được nhiều kinh nghiệm khi lựa chọn sản phẩm chất lượng để đảm bảo quyền lợi của khách hàng.

Ngày nay hầu hết đại đa số các công trình xây dựng đều cần phải sử dụng bê tông, tuy nhiên vấn đề ở đây chính là bề mặt bê tông phải đảm bảo tính thẩm mỹ cũng như chất lượng. Đây là một vấn đề khá nóng bỏng trong nhiều năm gần đây trong ngành xây dựng. Giải pháp duy nhất là chúng ta sử dụng ván ép phủ phim để đảm bảo những yếu tố trên. Ván ép phủ phim hội tụ đầy đủ những gì mà chủ thầu cũng như chủ nhà cần đến chúng. Với những ưu điểm nổi trội này chắc chắn sẽ không làm phụ lòng mong đợi của các thợ và nhà thầu. Đây là một số lý do bạn nên chọn hệ ván gỗ phủ phim để đạt hiệu suất làm việc cao nhất mà các nhà thầu nên chọn cho quá trình thi công

09Tháng 03

CÁCH BẢO QUẢN VÁN ÉP PHỦ PHIM

Bảo quản ván ép cốp pha phủ phim giữ được chất lượng tốt trong thời gian dài là mong muốn của bất cứ kĩ sư thi công nào. Nếu bạn chưa biết cách, hãy tham khảo ngay những mẹo bảo quản đơn giản mà hiệu quả sau đây của AAWOOD nhé!